Chute Technology is celebrating a decade of tackling some of the toughest materials handling challenges in the mining, resources, minerals processing, and ports industries.

Now, as the industry embraces automation and sustainability, Chute Technology is evolving to meet the moment with holistic solutions that optimise flow, curtail downtime, and reduce environmental impact.

With more than 100 chute and conveyor projects completed across ports, surface plants, and underground operations, Chute Technology’s track record shows a blend of responsiveness, practical insight, and engineering discipline.

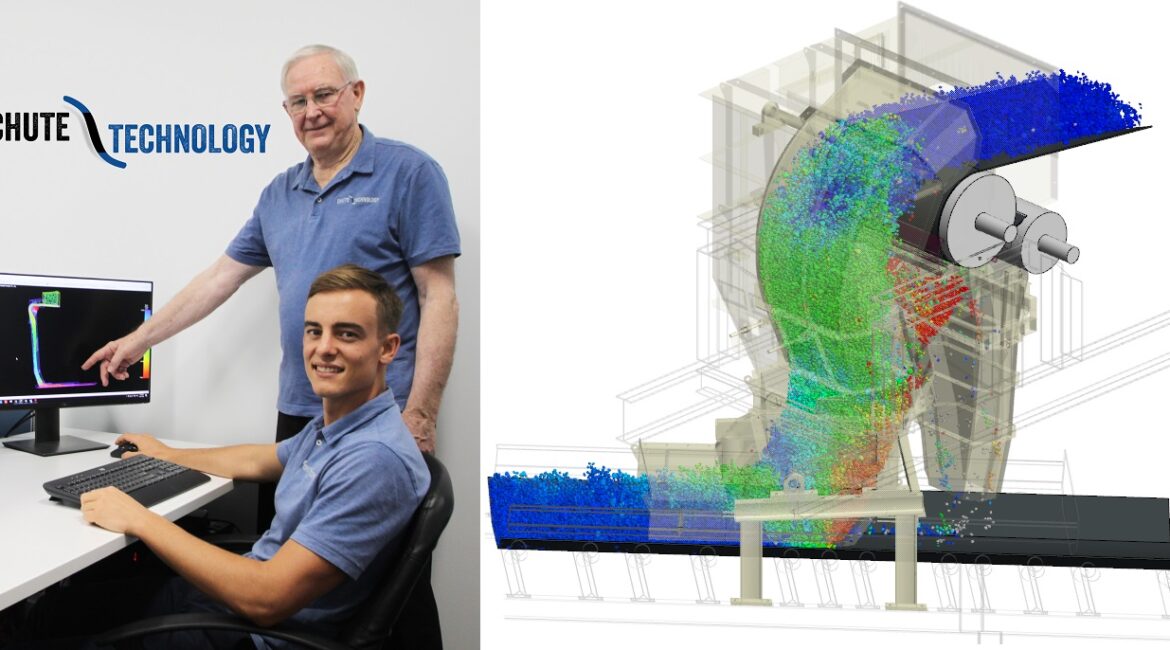

“Customers come to us because we align with their vision, we get it right the first time, and we deliver solutions that make their operations more productive and profitable,” says Chute Technology Principal Engineer, Dennis Pomfret.

Based in Charlestown, near Newcastle, NSW, Chute Technology has a broad range of experience, including coal and hard rock mining operations, ports, surface plants, and underground environments.

“Chute Technology’s success stems from its investment in both people and tools – combining deep technical knowledge with on-site experience and a clear understanding of client goals,” says Dennis.

Chute Technology Senior Mechanical Engineer Gian Naldi, adds, “We’re not afraid of the new. We constantly push the boundaries to deliver designs that not only work on paper, but work in the real world, and deliver a clear and measurable return to our clients.”

Engineering results that matter

Recent large-scale project work – delivered in collaboration with sister company DPE Engineering – highlights Chute Technology’s growth from problem solvers to trusted partners on multi-million-dollar developments. Examples include:

- Remote underground mining system: Full mechanical design for a 27-conveyor system operated remotely underground. From concept to commissioning in under a year, this project began with an idea brought to Chute Technology and ended with a fully functional, integrated system.

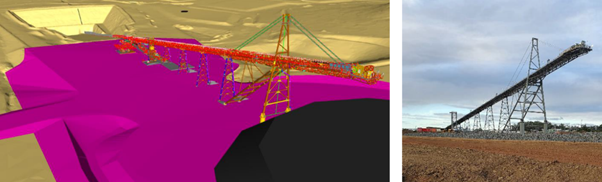

- 800m stacker conveyor for a Queensland mine: Mechanical, structural, and geotechnical engineering delivered for a 450-tonne steel conveyor stacker, built 100m high. Completed on time, on budget, and in partnership with multiple contractors – a $26 million success story.

- Refurbishment of a major NSW underground mine: After being closed since 2006, this mine was brought back into operation with Chute Technology’s help, covering feasibility, mechanical engineering, belt calculations, tenders, QA, and more. The 5km of new trunk conveyors and equipment form part of an $11 million project – and the relationship continues as new underground tunnels are developed.

“These are great examples that showcase how our capabilities have grown from individual material handling problems, through to utilising multiple disciplines of engineering across multi-million dollar mining operations,” says Gian.

“At the end of the day, our success is measured by our customers’ success. We make it easier to get things done, we reduce rework, and we help them make money. Our focus is on long term partnerships that continue to deliver value,” he concludes.