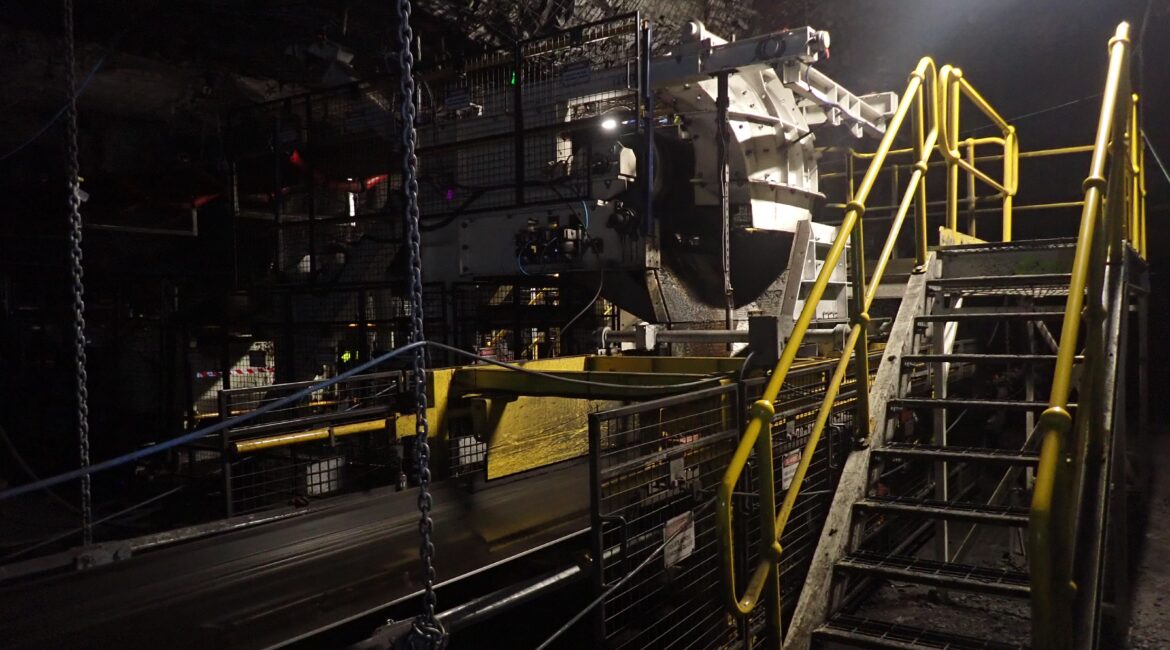

A new modular chute and conveyor solution is providing reliability for an Australian coal mining operation.

The mine operator engaged Chute Technology for an all-in-one solution, including design, project management, engineering, procurement, and manufacturing.

Chute Technology is a specialist Australian materials handling and engineering problem solver, with particular expertise both locally and internationally in coal, minerals, and transfer chutes.

Chute Technology Engineer, Gian Naldi, said that while transfer chutes, DEM software, and engineering have been their core areas of expertise, the company has invested in new Belt Analyst software, which has allowed them to design conveyors as well.

“Belt Analyst is the most recognised conveyor design software, and it makes sense for us to add this to our repertoire when we are designing complete materials handling systems,” says Gian, who works closely with Chute Technology Director, Dennis Pomfret, who has decades of local and international experience in problem-solving and improving resources engineering opportunities.

The new underground chute is a totally modular system, and is connected to approximately one kilometre of conveyor to transport material out of the mine.

Expanded capabilities

The new conveyor capabilities ideally complement Chute Technology’s materials handling expertise, which has focused on chutes, dust suppression, dewatering, shiploaders and a broad range of material flow issues.

“Since adding this capability, we’ve worked on a number of conveyors, both new designs and refurbishments. With refurbished conveyors, we can certify conveyor equipment is fit-for-purpose and safe to use underground,” says Gian.

“We are aiming to be a one-stop-shop for materials handling needs, so that we can provide everything from design to commissioning, to save customers time dealing with multiple companies,” he said.

Fast and successful commissioning

The new modular chute and conveyor system was all installed on schedule, and Chute Technology was pleased that feedback from the site was that everything has worked well since commissioning. The conveyor was wet commissioned with no downtime for adjustments to the conveyor and the transfer chute.

“Installation and commissioning were all on time, without delays, which is credit to the entire team involved with this project,” said Gian.

Underground expertise and problem solving

Chute Technology has extensive experience in underground equipment and problem solving. “We were recently approached with a unique problem, which we took on, knowing we have the design, software, engineering, and installation experience to solve the industry’s problems,” said Gian.

In this case, a mine was seeking lightning protection for its underground conveyors, to prevent a situation where lightning strikes part of the equipment on the surface, and travels through the conveyor structure to the underground mine, where it could cause serious damage. This was a regulation requirement to maintain the safety of all workers in and around the mine.

“Underground environments have a potential for explosions to occur if the right safety measures are not followed, which is why operators are so meticulous about keeping equipment compliant to Standards,” says Gian.

“We engineered a conveyor structure that had an air gap between the surface and underground sections of the conveyor, so that in the event of a lightning strike, the current could not progress into the underground mine,” he said.

“These are the sorts of challenges we are best equipped to solve. We have the in-house expertise, software, and capabilities to handle just about any mining, minerals handling or material flow problem, and create a customised solution.”

If you have material handling issues, or need conveyor or chute expertise, contact Chute Technology today